INTERVENTION-LESS ZONAL

PRODUCTION INSIGHT

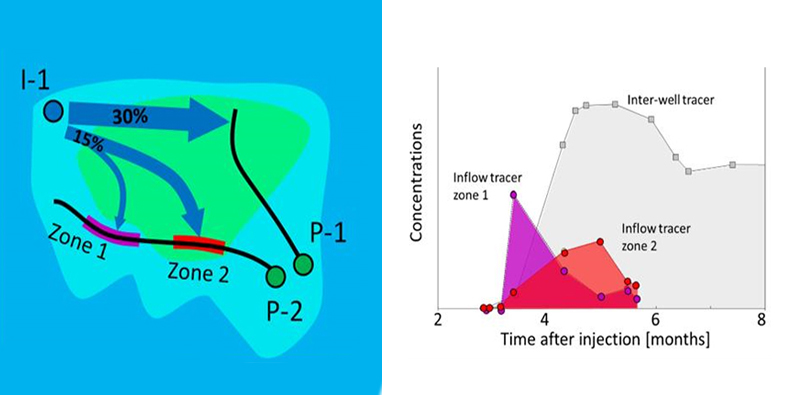

Risk-free zonal flow profile

As the domain specialists focusing solely on tracer technology, RESMAN offers a depth and breadth of risk-free solutions for remote reservoir monitoring to measure the zonal inflow for gas, oil and water, inflow and zonal flow performance profile.

Zonal Flow Performance Assessment

Flow Confirmation

Water Breakthrough Locations

Clean-up Confirmation

Long-term Trend Analysis

Zonal Productivity

Zonal Isolation

IN-DEPTH RESERVOIR INSIGHT

RESMAN offers precise measurements and assessment of the reservoir condition, providing crucial information for managing and mitigating unwanted fluid intrusion.

TROUBLESHOOTING

Inflow of substances, leaks, and inefficiencies.

ANALYSIS

Patterns and dynamics of incoming fluids.

DATA

Quantitative data on the rate and distribution of inflows.

INSIGHT

Expanded insight into the reservoir performance throughout the production life.

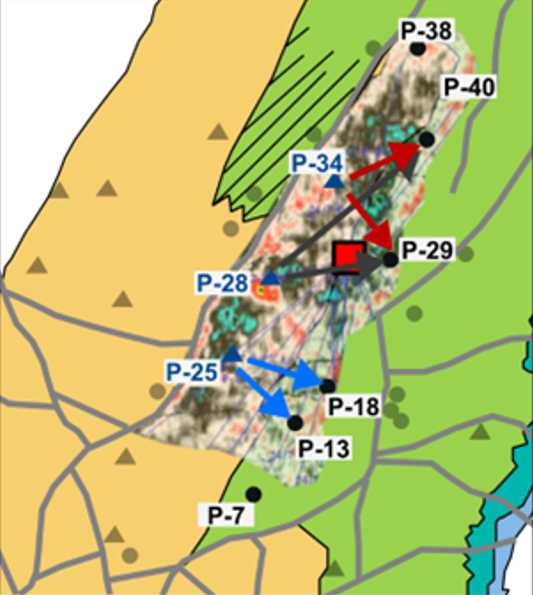

WATER BREAKTHROUGH

Understanding which zones are the source of water production.

PRODUCTION PROFILE CHARACTERIZATION

Detailed profile of fluid production from different zones, enabling a more nuanced understanding of reservoir behavior.

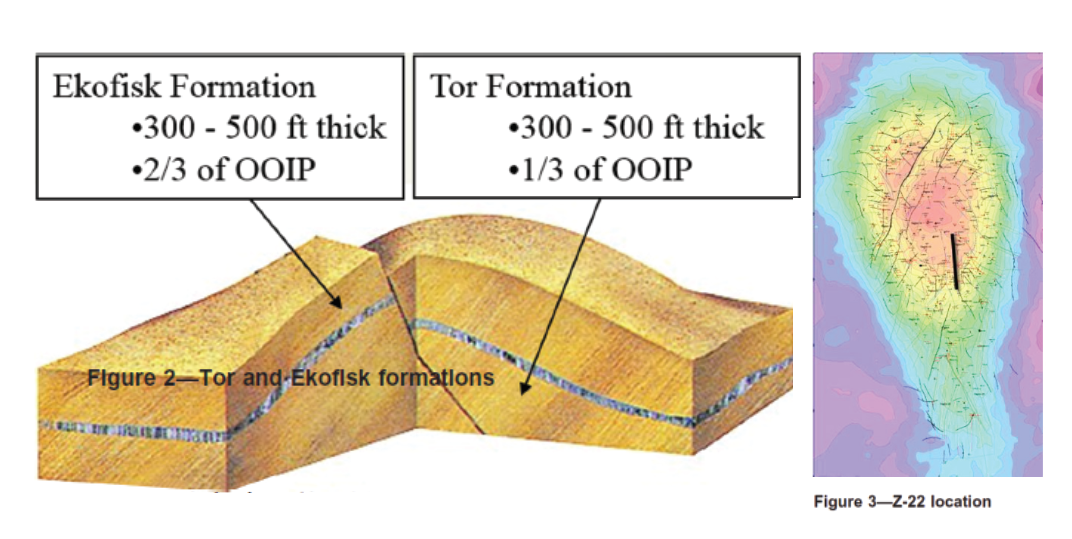

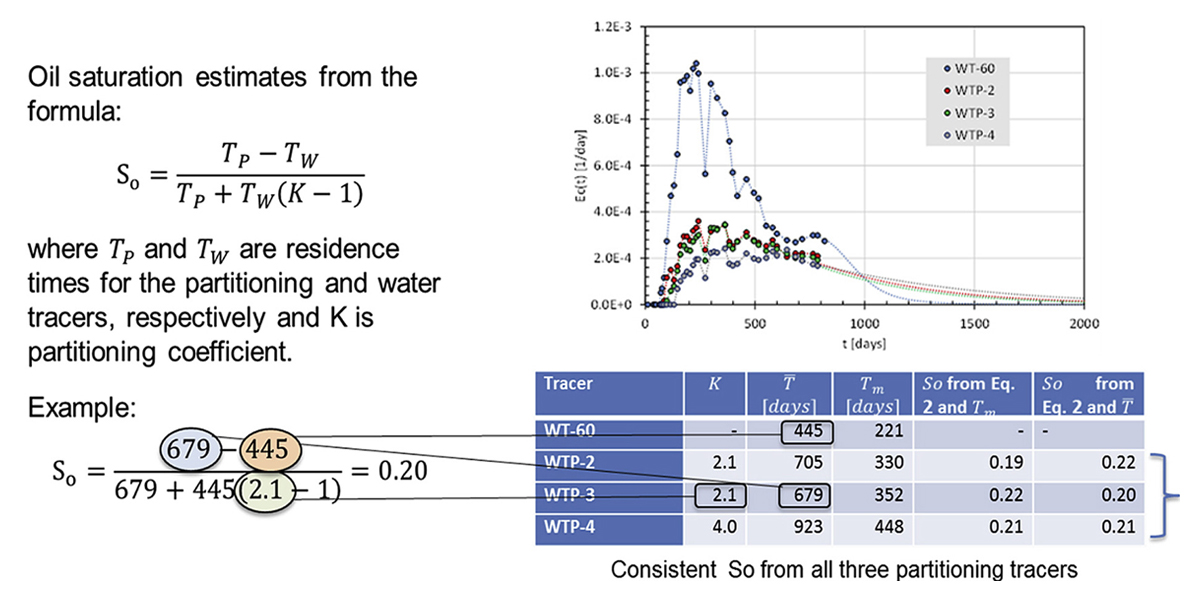

RESERVOIR CHARACTERIZATION

Evaluation of reservoir heterogeneity to better understand how fluids move through different layers and formations within the reservoir.

OIL BYPASSING MEASUREMENT

Revealing areas where oil is bypassing production zones, allowing for targeted intervention and management owing to zonal analysis for Improved Oil Recovery (IOR).

ENHANCING WELLBORE INTEGRITY

Offering validation of completion components such as sliding sleeves and flow control valves.